Introduction

In the world of industrial components and machinery, PLG supplies serve as the backbone of efficiency and productivity. Whether you are operating a manufacturing unit, managing an industrial warehouse, or handling a commercial engineering project, you will encounter the need for reliable, durable, and specialized components. That’s where PLG supplies come into play. Known for their consistency, precision, and utility, PLG supplies are indispensable in several sectors ranging from construction to electronics, automation, manufacturing, energy, and mechanical operations.

This article presents a comprehensive exploration of PLG supplies — what they are, what types of supplies are typically categorized under PLG, their roles in different industries, benefits of using high-grade PLG materials, maintenance tips, and how to choose the right supplier. The aim is to offer a complete resource for professionals, business owners, engineers, and procurement teams looking to optimize their operations through informed purchasing decisions regarding PLG supplies.

What are PLG Supplies?

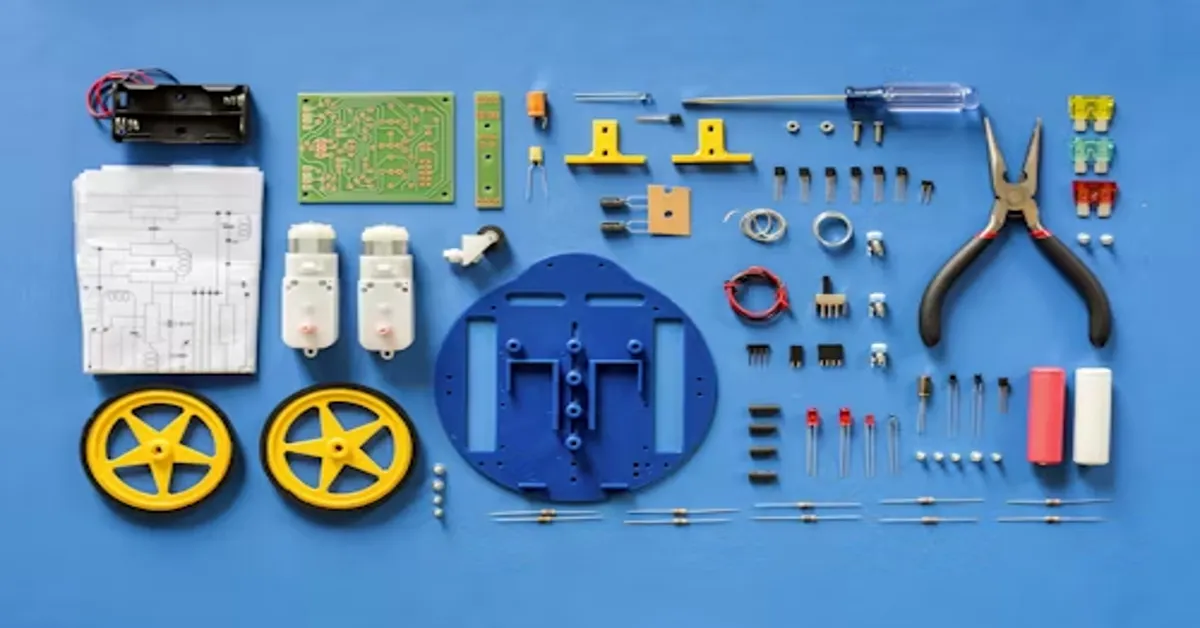

PLG supplies refer to a specialized category of industrial components and support products used in mechanical, electronic, hydraulic, and automation systems. While the term “PLG” is not always universally defined by a single product type, it generally encapsulates components that are precision-engineered, lightweight yet strong, and geared for high-performance applications. These supplies often include but are not limited to:

- Pneumatic components

- Linear guides

- Gearboxes and motors

- Sensors and actuators

- Industrial valves and fittings

- Seals, bearings, and lubrication systems

These products are crucial for movement, control, and connectivity in any type of automated or semi-automated system. They are often used in manufacturing lines, robotic systems, energy-efficient machinery, and even aerospace components due to their reliability and performance characteristics.

Categories of PLG Supplies

PLG supplies can be classified into multiple functional categories depending on their application. Below are the core categories and a deeper look into each.

1. Pneumatic and Hydraulic Components

These components control fluid or air pressure within a system. They are used in automation for controlling movement in machines. Common types include:

- Pneumatic cylinders

- Air filters and regulators

- Hydraulic pumps

- Fluid connectors

They are known for their robustness and ability to perform in heavy-duty environments where electrical solutions might be less effective or safe.

2. Linear Motion Systems

Linear motion is critical in any machinery where items need to be moved along a straight path with precision. PLG supplies in this category include:

- Linear bearings

- Rails and shafts

- Linear actuators

- Ball screws

Such components are fundamental in CNC machinery, 3D printers, packaging equipment, and laboratory testing devices.

3. Gearboxes and Motors

PLG gearboxes and motors are engineered for torque conversion and motion control. Common types include:

- Planetary gearboxes

- Servo motors

- Stepper motors

- AC/DC gear motors

Their efficiency and control features make them ideal for robotic arms, conveyors, and industrial automation.

4. Sensors and Control Devices

Sensors detect physical changes such as temperature, pressure, and position. Key items include:

- Proximity sensors

- Encoders

- Flow meters

- Limit switches

Paired with actuators and motors, they enable responsive control systems in smart manufacturing setups.

5. Fasteners, Seals, and Fittings

These are the support materials that hold everything in place or ensure leak-proof operation. Examples include:

- O-rings

- Threaded fasteners

- Quick connectors

- Industrial clamps

They are small but critical for safe and effective machine operation.

Key Benefits of PLG Supplies

Using PLG supplies offers a range of practical and economic benefits. These advantages span from performance improvements to cost savings and longevity. Here’s an in-depth look at why industries rely heavily on these components.

1. Precision and Accuracy

PLG supplies are engineered for precision applications. Whether it’s a sensor that detects millimeter-level changes or a gearbox that ensures precise rotation, these products contribute significantly to the accuracy of machines.

2. Durability and Reliability

Manufactured using high-grade materials such as stainless steel, aluminum alloys, and polymer composites, PLG supplies are built to withstand harsh industrial environments. They are often resistant to corrosion, extreme temperatures, and mechanical wear.

3. Reduced Downtime

Reliable PLG supplies translate to less breakdown and maintenance. This directly affects productivity, especially in industries where operational downtime can result in significant losses.

4. Energy Efficiency

Modern PLG components are designed to optimize energy usage. For example, motors are made to consume minimal power while delivering optimal torque, and pneumatic systems now come with smart control for air efficiency.

5. Versatility

PLG supplies are modular and can be used across various machines and platforms. This makes them cost-effective for companies with multiple product lines or systems.

Industries That Rely on PLG Supplies

PLG supplies are not limited to one specific sector. Their versatility and reliability make them essential across a wide range of industries.

1. Manufacturing

From automotive to electronics, PLG components such as linear guides and gear motors are crucial for machine assembly, production lines, and quality control systems.

2. Automotive

The automotive industry uses PLG gearboxes, sensors, and valves for vehicle assembly, testing, and automation of robotic systems.

3. Food and Beverage

Hygienic and corrosion-resistant PLG supplies are used in food packaging and processing equipment where cleanliness is crucial.

4. Pharmaceuticals

In pharmaceutical manufacturing, PLG supplies ensure accurate dosing, sterile processing, and precision-controlled environments.

5. Aerospace and Defense

Highly specialized PLG products are used in control systems, simulation equipment, and testing instruments in the aerospace and defense industries.

6. Renewable Energy

PLG gear motors and linear actuators are often integrated into solar panel tracking systems and wind turbines for alignment and efficiency.

Choosing the Right PLG Supplies

When it comes to sourcing PLG supplies, the selection process is crucial. Choosing the wrong product can lead to inefficiencies, increased costs, or even operational failure. Here’s what to consider:

1. Material Compatibility

Ensure that the materials used in the PLG components are compatible with the environmental and chemical conditions of your facility.

2. Performance Requirements

Understand the torque, speed, pressure, and load-bearing requirements of your application. Choose components that exceed, rather than just meet, these thresholds.

3. Supplier Credibility

Always source from trusted manufacturers or suppliers who offer warranties, customer support, and post-sale services.

4. Customizability

Look for components that can be tailored or configured according to your system’s requirements. Modular systems save both time and cost in the long run.

5. Compliance and Standards

Check if the products meet international quality standards such as ISO, RoHS, or CE certifications. This ensures reliability and safety.

Maintenance and Handling of PLG Supplies

Even the best PLG supplies need proper handling and maintenance to perform at their best. Here are some essential tips:

- Regular Inspections: Schedule routine checks for wear and tear, alignment, and functionality.

- Proper Storage: Keep components in clean, moisture-free environments to avoid corrosion.

- Lubrication: Ensure all moving parts are adequately lubricated as per manufacturer instructions.

- Training: Train your technical staff to install and handle components correctly to prevent misuse.

- Use OEM Parts: For replacements, always opt for original parts instead of generic ones to maintain system integrity.

Future Trends in PLG Supplies

As industries evolve with technologies like AI, robotics, and IoT (Internet of Things), PLG supplies are also undergoing transformation. Smart sensors that can transmit data, actuators with self-diagnostic features, and motors integrated with digital feedback are becoming standard. Sustainability is another trend, with companies focusing on recyclable materials and energy-efficient designs. Keeping an eye on these innovations will help businesses stay ahead of the competition.

Conclusion

PLG supplies form the core of modern industrial operations. Their range of applications, from motion control to automation and safety systems, makes them indispensable in a variety of industries. Whether you’re managing a large-scale manufacturing facility or operating a small assembly line, choosing the right PLG components can significantly enhance performance, reduce downtime, and save operational costs.

Understanding the different types of PLG supplies, their benefits, and maintenance requirements empowers professionals to make informed decisions that align with long-term business goals. As technology continues to evolve, PLG supplies will play an even greater role in ensuring that industrial systems are smarter, faster, and more efficient.

ALSO READ: What is Nomurano? A Holistic Concept Rooted in Mindful Living

Frequently Asked Questions (FAQs)

1. What does PLG stand for in industrial supplies?

While “PLG” may vary in definition across industries, it typically refers to a category of high-performance industrial components used for precision linear gear systems and motion control applications.

2. What are the main types of PLG supplies?

They include pneumatic cylinders, gearboxes, linear motion systems, sensors, actuators, bearings, and industrial valves among others.

3. Where are PLG supplies commonly used?

PLG supplies are used in manufacturing, automation, automotive, food processing, pharmaceuticals, aerospace, and renewable energy industries.

4. How do I maintain PLG components for longevity?

Ensure regular inspection, proper lubrication, correct installation, and use of OEM (Original Equipment Manufacturer) parts for maintenance.

5. Why should I choose certified PLG suppliers?

Certified suppliers provide high-quality, tested components that meet industry standards, ensuring safety, reliability, and compliance with regulations.