In the world of polymer film production, the blow-up ratio is more than just a technical metric—it’s a critical factor that shapes the quality, performance, and economics of plastic films. Whether you’re a manufacturer, packaging engineer, or simply an informed consumer, understanding the blow-up ratio provides deep insights into how flexible packaging is engineered for diverse applications, from food wrapping to industrial liners.

At its core, the blow-up ratio (BUR) refers to the ratio of the final film’s width to the diameter of the die used in the blown film extrusion process. It influences mechanical properties like film strength, clarity, barrier performance, and cost-efficiency. This article takes you inside the science and applications of blow-up ratio, explaining how it affects film characteristics and what recent advancements are reshaping its use in the modern packaging industry.

What Is Blow-Up Ratio?

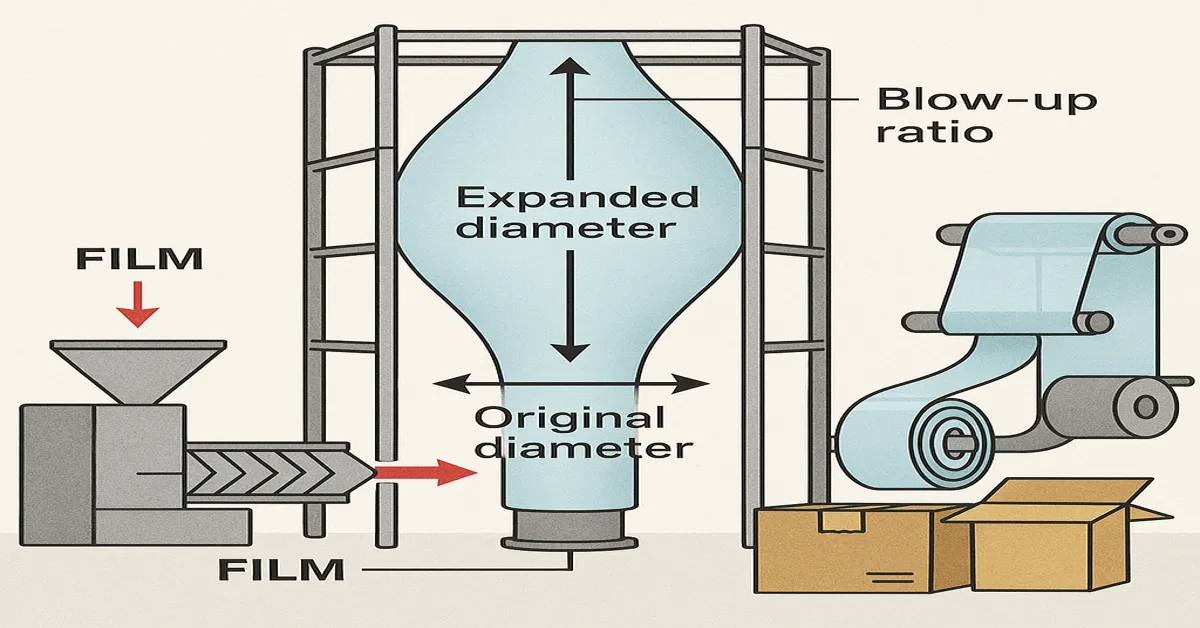

Blow-up ratio (often abbreviated as BUR) is a term used primarily in the blown film extrusion industry. It describes the extent to which a molten polymer tube is expanded during extrusion. This expansion is performed by inflating the tube with air and stretching it in a vertical tower, forming a bubble that is cooled and flattened into a film.

The Mathematical Formula

The blow-up ratio is mathematically defined as:

Blow-Up Ratio (BUR) = Bubble Diameter / Die Diameter

Where:

- Bubble Diameter refers to the final diameter of the expanded film bubble.

- Die Diameter is the diameter of the circular extrusion die through which the molten polymer is initially pushed.

For example, if a 100 mm die produces a film bubble of 300 mm, the blow-up ratio is 3:1.

Why Blow-Up Ratio Matters

The BUR directly affects the film’s mechanical properties, including:

- Tensile Strength

- Clarity and Transparency

- Barrier Properties

- Film Thickness Distribution

- Shrinkage Behavior

Influence on Molecular Orientation

When the film is stretched during extrusion, polymer molecules align themselves both in the machine direction (MD) and the transverse direction (TD). A higher BUR stretches the film more in the transverse direction, leading to better balance between MD and TD properties. This is crucial in applications like food packaging, where uniform strength and barrier performance are essential.

Optimal Blow-Up Ratios for Different Applications

Different film applications require different BURs. Below is a general guide:

| Application | Typical BUR Range | Reason |

|---|---|---|

| Grocery bags | 2:1 – 3:1 | Balanced strength and cost efficiency |

| Shrink wrap | 3:1 – 4.5:1 | High shrinkage and clarity |

| Agricultural films | 1.5:1 – 2:1 | Higher thickness and strength |

| High-barrier packaging | 2.5:1 – 3.5:1 | Improved molecular orientation |

| Medical packaging | 3:1 – 4:1 | Consistency in strength and clarity |

Advances in Blow-Up Ratio Management

In recent years, technological developments in die design, air ring control, and cooling techniques have allowed manufacturers to fine-tune BUR with high precision.

1. 3D Air Rings

These adjustable air rings ensure consistent cooling, which allows for higher BURs without compromising stability. They are especially useful for multi-layer films requiring tight thickness tolerances.

2. Infrared Thickness Profiling

Modern blown film lines use infrared gauges to monitor film thickness in real time. When BUR affects the uniformity of the film, the system automatically adjusts die bolts or air rings to correct the imbalance.

3. Computer-Controlled Extrusion

Extrusion systems now use predictive algorithms to control BUR dynamically, allowing for faster production, reduced waste, and improved quality assurance.

The Interplay Between Blow-Up Ratio and Other Process Parameters

Blow-up ratio doesn’t work in isolation. It is closely linked with several other factors:

- Draw-down ratio (DDR): This measures how much the film is stretched in the machine direction.

- Frost line height (FLH): The height at which the molten polymer solidifies. A higher BUR often requires a higher FLH for better cooling.

- Cooling efficiency: More rapid cooling can stabilize higher BURs, reducing wrinkles and improving optical clarity.

Understanding the balance between these parameters is critical for engineers designing extrusion lines and quality control teams monitoring consistency.

Challenges of High and Low Blow-Up Ratios

High BURs (above 3:1)

- Pros:

- Better strength in the transverse direction

- Improved optical clarity

- Thin, lightweight films possible

- Cons:

- Increased complexity in maintaining bubble stability

- Higher demand on cooling systems

- Potential for uneven film thickness

Low BURs (below 2:1)

- Pros:

- Simpler bubble control

- Suitable for thick or heavy-duty films

- Cons:

- Poor balance in MD and TD strength

- Less efficient material usage

Environmental Impact of Blow-Up Ratio Decisions

In the age of sustainability, manufacturers are rethinking how blow-up ratios impact material consumption and recyclability.

- Lower BURs tend to use more material for the same film area, increasing carbon footprint.

- Optimized BURs allow for thinner, stronger films that reduce material waste and improve transportation efficiency.

Recent innovations in biodegradable and compostable films have also introduced new constraints on BUR. These materials often require lower processing temperatures and different expansion ratios, challenging traditional BUR norms.

Case Study: Blow-Up Ratio in Multi-Layer Barrier Films

Multi-layer films used for vacuum sealing and high-barrier packaging (like cheese or meat products) often require very precise BUR settings to ensure performance. Here’s how it works:

- Outer Layer: Often polyethylene or polypropylene, offering sealability and printability.

- Core Layer: Usually ethylene vinyl alcohol (EVOH) or nylon, providing oxygen barrier.

- Inner Layer: Polyethylene for food contact and sealing.

A BUR of around 3:1 is often chosen to ensure even distribution of all layers, especially in the transverse direction. Variations in BUR can cause layer inconsistencies that lead to failure in barrier performance or poor sealing.

Common Mistakes in Managing Blow-Up Ratio

- Over-inflating the bubble, leading to instability and wrinkles

- Inconsistent cooling, causing variations in thickness

- Improper die design, not supporting desired BUR

- Ignoring polymer behavior, some polymers cannot be stretched at high BURs without defects

Avoiding these pitfalls requires a combination of engineering expertise, real-time monitoring, and material-specific processing knowledge.

Future Trends in Blow-Up Ratio Technology

As packaging demands shift toward sustainability, automation, and customization, the role of BUR is evolving.

1. AI-Controlled Extrusion Lines

AI systems are beginning to learn the optimal BUR for different film types based on data from previous runs, adjusting parameters automatically.

2. Digital Twins in Film Design

Engineers are using digital simulation tools to test different BURs virtually before production, saving time and materials during the development phase.

3. Flexible Packaging for E-Commerce

Flexible mailers and cushion films used in e-commerce require BURs that balance toughness with lightness. Manufacturers are now tailoring BUR settings specifically for these applications.

Conclusion: The Strategic Importance of Blow-Up Ratio

To the untrained eye, blow-up ratio may seem like a niche metric in film production. But in reality, it plays a central role in determining the physical, visual, and functional qualities of the plastic films that wrap our food, protect our products, and even support medical packaging.

Understanding BUR empowers stakeholders across the value chain—from raw material suppliers to brand owners—to make better choices that balance performance, cost, and sustainability. As materials and machinery evolve, mastering the blow-up ratio will remain a critical skill in the global packaging landscape.

ALSO READ: What Is a Quartist? Understanding the Role, Relevance, and Cultural Evolution of a Quartist

FAQs

1. What is an ideal blow-up ratio for standard grocery bags?

Most grocery bags use a BUR between 2:1 and 3:1 to balance film strength, clarity, and cost-effectiveness.

2. Can changing the blow-up ratio fix film thickness issues?

Yes, adjusting BUR can help even out thickness, especially when used with other controls like air rings and die bolts.

3. How does blow-up ratio affect shrink film performance?

Higher BURs generally lead to better shrinkage properties and clarity, essential for effective shrink wrapping.

4. Is BUR applicable in cast film extrusion?

No, BUR is specific to blown film processes. Cast film processes do not involve bubble expansion and use different orientation methods.

5. Do biodegradable films have the same BUR range as conventional plastics?

Not always. Biodegradable films often require lower BURs due to different thermal and mechanical properties, which affects processing.