In the world of textiles and garment construction, “Nahttypen” refers to the different types of seams used to join fabrics. While this term originates from German—“Naht” meaning “seam” and “Typen” meaning “types”—the concept is universal in fashion, engineering, and technical textiles. Understanding Nahttypen isn’t just for tailors or designers. From medical uniforms to aerospace materials, seam types determine how fabrics behave under stress, how they age, and how they perform in specific environments.

In this guide, we break down what Nahttypen are, how they’re classified, and why each type matters in practical and creative industries today.

What Are Nahttypen?

Nahttypen are classifications of seams used in fabric construction, each with a specific structural and aesthetic purpose. Every seam is defined by the way fabric pieces are joined—whether flat, folded, reinforced, or decorative. Seam types vary by:

- Strength

- Flexibility

- Stitching method

- Visibility

- Suitability for different textiles

Understanding the right Nahttyp for a project is critical to its success. Choose the wrong seam, and a dress could fall apart, or a fireproof uniform could fail in extreme heat.

The Anatomy of a Seam

Before diving into types, let’s understand what a seam is composed of:

- Seam Line – Where two pieces of fabric are joined.

- Seam Allowance – The extra fabric beyond the seam line that provides strength.

- Stitching – The thread method used to bind the fabrics.

- Finishing – How the edge is treated to prevent fraying or improve comfort.

The way each of these elements is handled defines the Nahttyp.

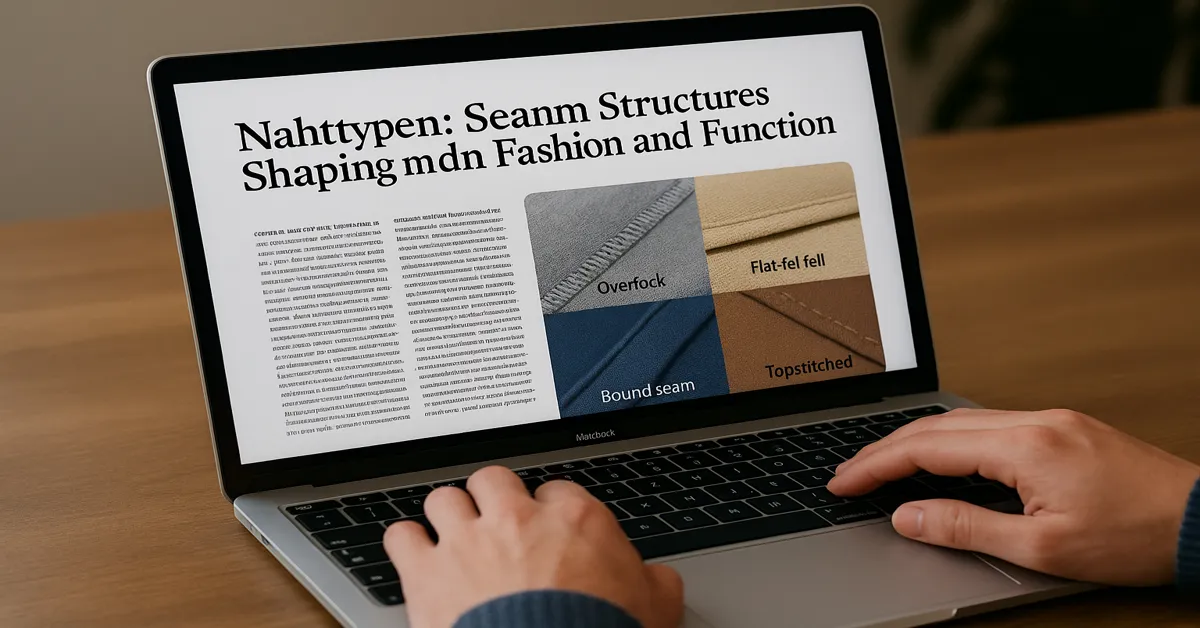

Common Nahttypen and Their Applications

Here is a breakdown of the most widely used Nahttypen in modern textile industries, alongside their technical uses and benefits.

Table: Overview of Nahttypen and Their Uses

| Seam Type (Nahttyp) | Description | Key Use Case | Strength Level | Visibility |

|---|---|---|---|---|

| Plain Seam (Geradstichnaht) | Basic seam joined with single stitch | Everyday garments, linings | Moderate | Low |

| Flat-felled Seam (Kappnaht) | Folded and double-stitched for durability | Denim, uniforms, outdoor wear | Very high | Medium |

| French Seam (Französische Naht) | Enclosed raw edges inside folds | Lightweight fabrics like silk | Medium | Low |

| Lapped Seam (Überlappnaht) | One piece overlaps the other | Technical textiles, sports gear | High | High |

| Bound Seam (Einfassnaht) | Seam edge enclosed with bias tape | Lingerie, premium interiors | Moderate | Variable |

| Flatlock Seam (Flachnaht) | Edges abut and are joined with flat stitch | Activewear, stretch fabrics | High | Low |

| Welt Seam (Paspelnaht) | Similar to flat-felled with added edge | Structured garments, coats | High | High |

| Double Stitched Seam (Doppeltnaht) | Two parallel rows for added strength | Workwear, industrial applications | Very high | Medium |

Why Do Seam Types Matter Today More Than Ever?

In the past, seam types were primarily aesthetic or structural. Today, they are performance-critical. As fashion merges with function—think wearable tech or fireproof gear—seam choice affects:

- Thermal insulation

- Moisture wicking

- Pressure endurance

- Stretch recovery

Seams are no longer invisible heroes—they are the structural skeleton of modern clothing and gear.

Seam Classification: The Technical Criteria

Nahttypen are typically classified based on five key factors:

- Structural Function: Does the seam hold load or just shape?

- Appearance: Is it meant to be visible, decorative, or invisible?

- Textile Compatibility: Does it suit woven or knit fabrics?

- Production Complexity: Is it machine-efficient or labor-intensive?

- Durability: Can it withstand repeated wear, wash, or friction?

Some seam types are exclusive to industrial use, while others are optimized for mass-market apparel or couture.

Exploring the Major Nahttypen In Detail

1. The Plain Seam (Geradstichnaht)

Overview: The most common seam. Simple, quick, and foundational.

Use Case: Everyday apparel, especially in areas not exposed to high stress.

Pros:

- Fast to produce

- Minimal fabric waste

Cons:

- Weak without reinforcement

- Exposed raw edges unless finished

2. Flat-Felled Seam (Kappnaht)

Overview: Double-stitched with folded edges. Extremely durable.

Use Case: Jeans, jackets, and heavy-duty uniforms.

Pros:

- Strongest seam type

- Resistant to fraying and wear

Cons:

- Time-consuming

- Bulky on fine fabrics

3. French Seam (Französische Naht)

Overview: Neatly encloses raw edges within two lines of stitching.

Use Case: Blouses, lingerie, fine dresses.

Pros:

- Clean interior look

- No raw edges

Cons:

- Limited to lightweight fabrics

- Requires precision

4. Lapped Seam (Überlappnaht)

Overview: One fabric overlaps another; often topstitched.

Use Case: Waterproof or windproof garments, workwear.

Pros:

- Great for non-fraying materials

- High load capacity

Cons:

- Visible seam may limit aesthetic flexibility

5. Bound Seam (Einfassnaht)

Overview: Seam edges wrapped in bias tape or binding.

Use Case: Luxury finishes, sportswear linings.

Pros:

- Clean and polished appearance

- Protects skin from seam edges

Cons:

- Labor-intensive

- Adds bulk

6. Flatlock Seam (Flachnaht)

Overview: Created with special flatlock machines; minimal bulk.

Use Case: Yoga pants, swimwear, cycling gear.

Pros:

- Stretch-friendly

- Smooth against skin

Cons:

- Requires specialized machinery

- Not ideal for all fabrics

7. Welt Seam (Paspelnaht)

Overview: Decorative and strong, often seen in jackets or uniforms.

Use Case: Structured garments with stylistic accents.

Pros:

- Aesthetic detail

- Good durability

Cons:

- Not ideal for soft or draping fabrics

8. Double Stitched Seam (Doppeltnaht)

Overview: Two straight stitch lines for added reinforcement.

Use Case: Industrial clothing, high-movement zones.

Pros:

- Exceptional strength

- Machine-friendly

Cons:

- Less flexible

- Prominent look

Modern Innovation in Nahttypen: Smart Textiles and Seamless Engineering

In 2025, seam design has become more sophisticated than ever. With smart textiles and technical performance wear, we now see:

- Seamless bonding: Heat or ultrasonic welding replacing thread for waterproof garments.

- Conductive seams: Embedded wiring in seam lines for wearable tech.

- Reinforced 3D seams: Used in space suits and deep-sea diving gear.

The rise of automation and AI-assisted garment construction is also changing how designers think about seams—not just for performance, but for speed and waste reduction.

Cultural and Aesthetic Influence of Seam Types

Seams are becoming a design language. What was once hidden is now celebrated. Visible flatlock stitching in gym wear is a brand signal. Decorative welt seams in high fashion evoke authority or elegance. Even streetwear embraces seam play—overstitching, raw seams, or faux structural stitches that suggest rebellion or innovation.

In Japanese fashion, especially, the visible seam is part of the wabi-sabi aesthetic: valuing imperfection and craftsmanship.

Sustainability and Seam Types: What’s the Link?

Sustainable fashion must also consider seam choices:

- Easy-to-disassemble seams improve recyclability

- Strong, simple seams reduce returns and waste

- Seam design influences cutting patterns and fabric usage

Seamless knitting (like in some running shoes) reduces production waste. Expect seam science to become a pillar of circular fashion in the coming years.

How Professionals Choose the Right Nahttyp

Designers, tailors, and engineers weigh several factors before deciding on a seam:

- End use: Is the garment for fashion, sport, industry, or survival?

- Fabric type: Stretch vs. rigid, light vs. heavy

- Production scale: Handcrafted vs. automated

- Comfort level: Will it touch skin or be layered?

- Regulatory needs: Must it be fireproof, waterproof, etc.?

Learning About Nahttypen in Fashion Education

Institutions like Parsons, Central Saint Martins, and Hochschule für Technik und Wirtschaft Berlin teach seam taxonomy as part of foundational garment construction. Students study Nahttypen through physical samples, digital modeling, and prototyping.

Digital pattern-making software now includes seam simulation—letting designers see how seams perform before a single stitch is made.

Challenges in Seam Engineering Today

Despite advances, several challenges persist:

- Standardization: There’s no global seam coding system

- Training: Skilled seam technicians are in short supply

- Material mismatch: New fabrics often outpace seam tech

- Consumer expectation: People expect beauty, strength, and sustainability—often at odds

What’s Next for Nahttypen?

The future of Nahttypen lies in:

- AI seam optimization: Algorithms that adjust seam types to garment stress points

- Biodegradable threads and seals

- Transparent seam tracking for ethical manufacturing

- DIY-friendly seam tools that let home sewers access high-performance finishes

Conclusion

Nahttypen are far more than the hidden lines holding our clothes together. They’re engineering decisions, aesthetic statements, and ecological considerations rolled into each stitch. As industries evolve, seam types will increasingly determine not just how garments look—but how long they last, how well they perform, and how responsibly they’re made.

If knowledge is power, then understanding Nahttypen gives designers, manufacturers, and even consumers a rare kind of leverage—the ability to make, choose, or judge clothing not by brand or style alone, but by the craftsmanship sewn into every inch.

ALSO READ: GoMyFinance.com Saving Money: Rethinking Modern Budgeting and Financial Wellness

FAQs

1. What does “Nahttypen” mean in English?

“Nahttypen” is German for “seam types,” referring to classifications of how fabrics are joined in sewing or garment construction.

2. Why are seam types important in clothing?

Seam types affect strength, appearance, comfort, and longevity of garments. They’re critical for both form and function.

3. Which seam is best for sportswear?

Flatlock seams are ideal due to their flexibility, low profile, and comfort against the skin.

4. Are some seam types more sustainable than others?

Yes. Seams that are easy to dismantle, durable, or use less material contribute to sustainability.

5. How can I learn more about Nahttypen?

Fashion schools, textile engineering programs, and hands-on sewing practice are great starting points. Digital pattern tools also simulate seam behavior.